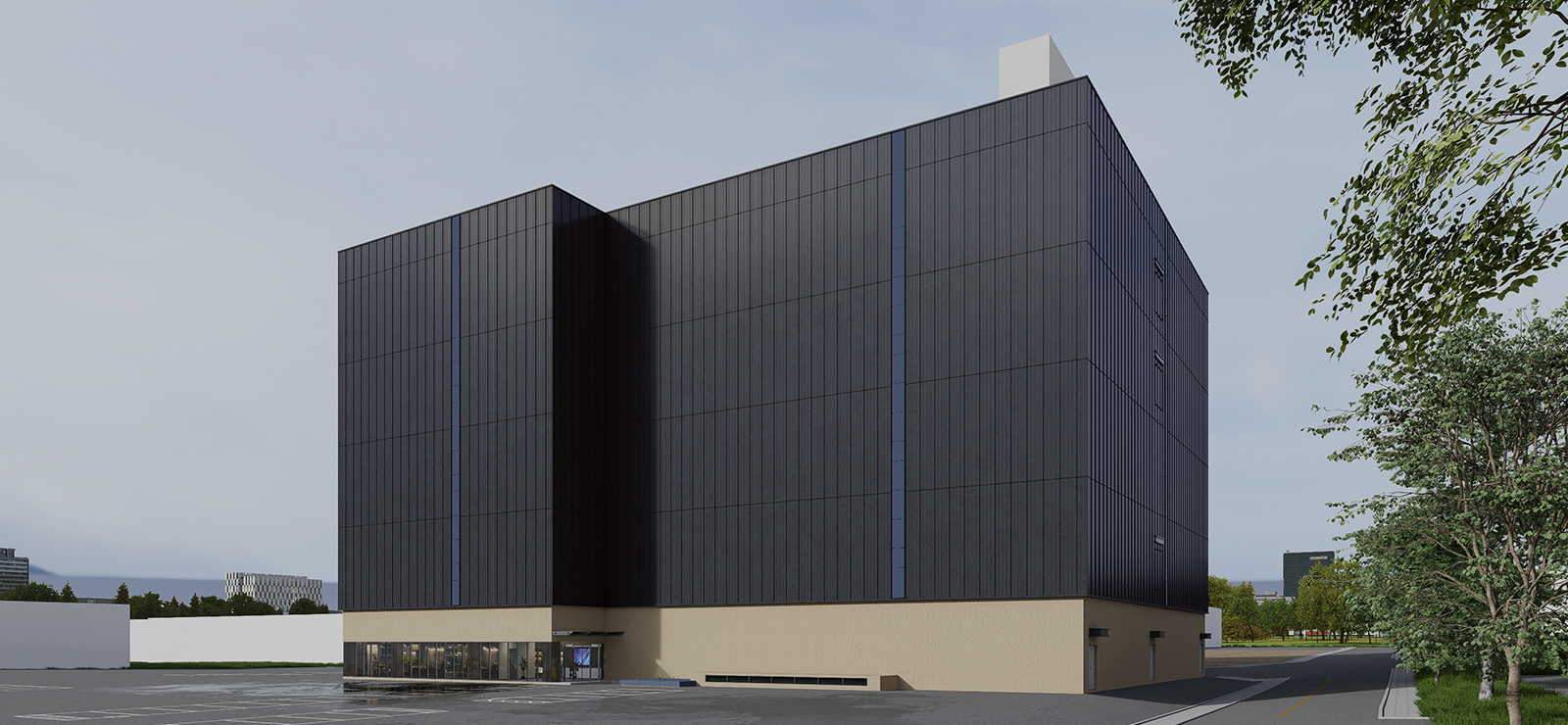

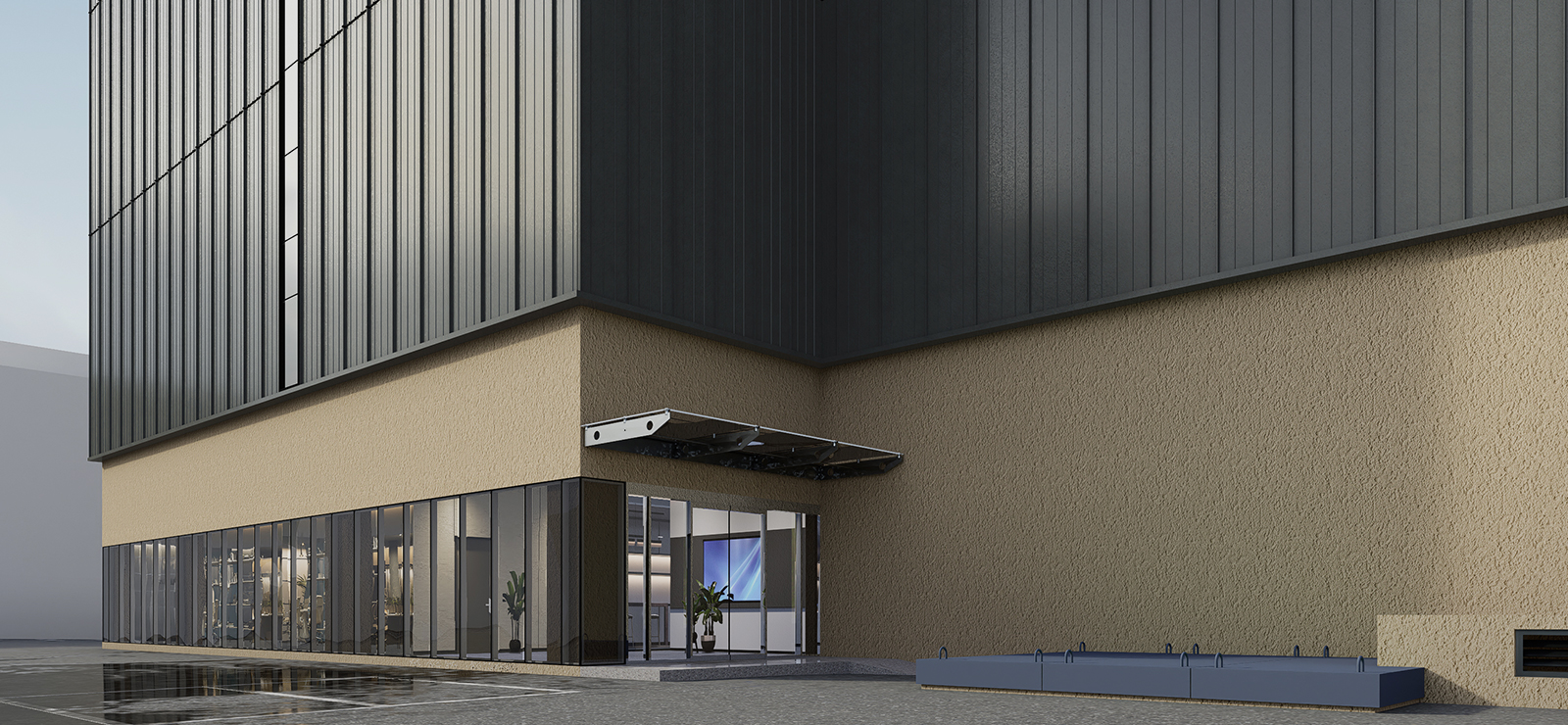

A state-of-the-art GMP plant compliant with international standard guidelines (PIC/S)

The concept design commenced in February 2023, followed by the start of construction in June 2024. The GMP facility,

consisting of one basement level and five above-ground floors, received completion approval on August 1, 2025.

The solid dosage line incorporates a BIN system designed to minimize material exposure.

The injectable line is equipped with a fully automated CIP/SIP system, a PUPSIT freeze dryer automatic loading/unloading system (ALUS),

and an O-RABS, all configured to ensure full compliance with EU-GMP Annex 1 requirements.

B1, 5 floors above ground

- RF

- Cooling tower, CDU, air handling units, dustcollectors, etc

- 5F

- Solid dosage packaging line, HVAC rooms, water treatment, compressed air facilities

- 4F

- Solid dosage production lines

(mixing, tableting, coating, sorting)

- 3F

- Injectable packaging line, HVAC rooms

- 2F

- Injectable production lines

(Vial+Freeze1,Vial+Freeze2, Ampoule)

- 1F

- Storage (raw materials, materials, finished products),power generation room, substation, HVAC rooms

- B1F

- Machinery rooms (boiler, refrigeration, firefighting,etc.)

(OSD)

800 million tablets/year

200 million capsules/year

Incorporation of a BIN system designed to minimize material exposure.

14.4 million vials/year

Freeze-dried 21.6 million vials/year

Installation of a fully automated CIP/SIP system,

a PUPSIT freeze dryer automatic loading/unloading

system (ALUS), and an O-RABS to ensure compliance

with EU-GMP Annex 1 requirements.

-

Concept Design

Feb 2023–Jun 2023 (delivered Oct 2023)

Feb 2023–Jun 2023 (delivered Oct 2023) -

Detail Design

2023.07~2024.03

2023.07~2024.03 -

Building Permit

May 2024 (construction permit Jun 2024,

May 2024 (construction permit Jun 2024,

demolition permit Jun 2024) -

Construction Period andWorkforce

Groundbreaking Ceremony for Second Plant: May 17, 2024

Construction Period: Jun 2024–Jul 2025 (14 months)

Workforce: Total workforce of 35,000 man-days

-

Target GMP Approval

2026.08~11

2026.08~11

Home

Home